BACK TO finale_winnerS

Honorary Mention: Architectural Category

GROM FROM THE EARTH… RETURN TO THE EARTH

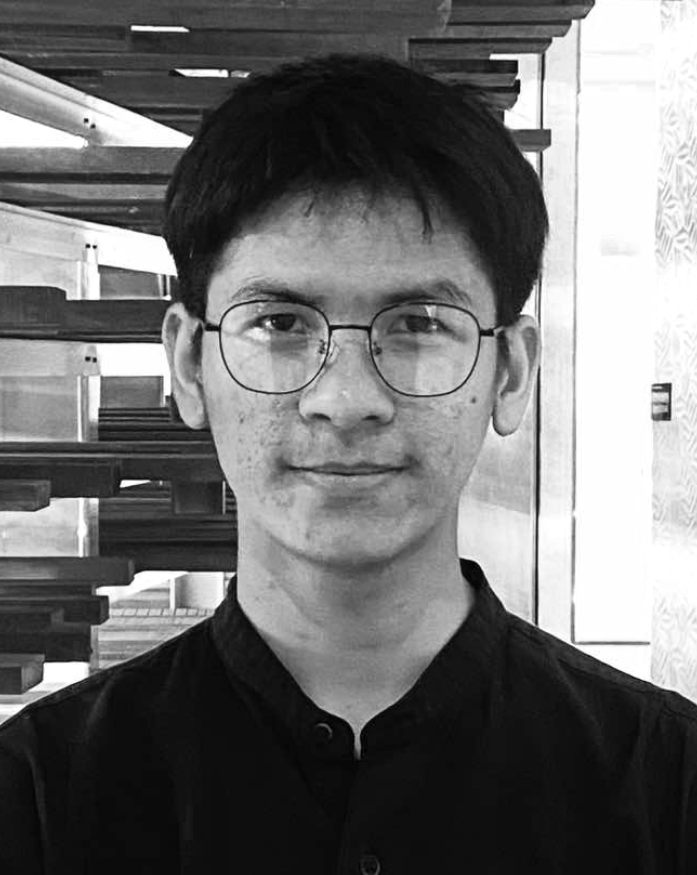

GROW FROM THE ERTH…RETURN TO THE ERTH Sugarcane is one of Thailand’s most important cash crops. About ten million rai are under cultivation, most of it in the Northeast, where the climate and soil nutrients are ideal for the plant’s growth. During harvest, farmers often burn the dry leaves to speed cutting. Although convenient, the […]

GROW FROM THE ERTH…RETURN TO THE ERTH

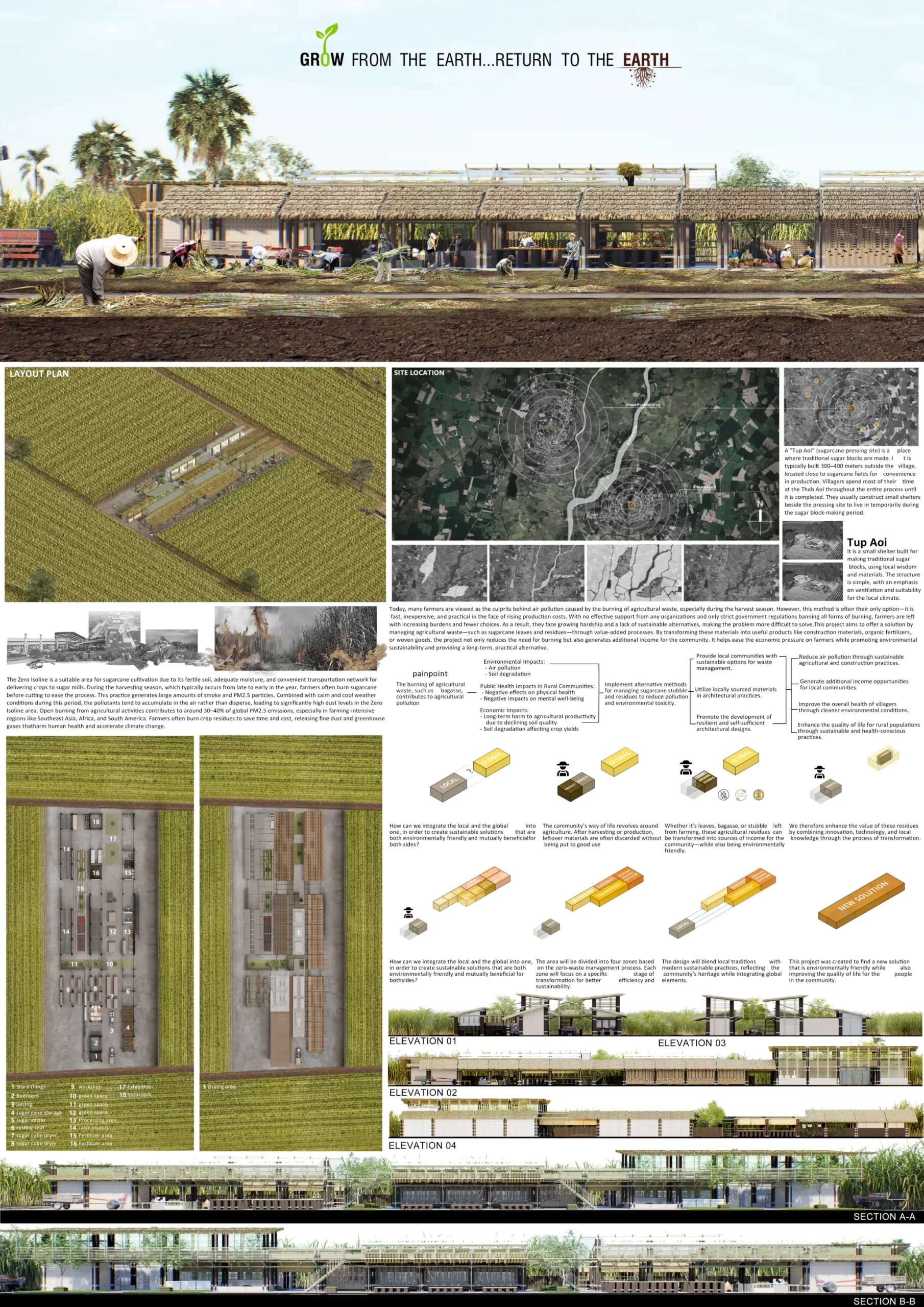

Sugarcane is one of Thailand’s most important cash crops. About ten million rai are under cultivation, most of it in the Northeast, where the climate and soil nutrients are ideal for the plant’s growth. During harvest, farmers often burn the dry leaves to speed cutting. Although convenient, the resulting smoke and fine dust harm local health, especially when resources in the production chain are poorly managed. Ban Nong Khae, Jumjang Sub-district, Kuchinarai District, Kalasin Province, is a village where most households grow sugarcane. At harvest time, farmers divide their crops into two portions: one is sold to a sugar mill, and the other is kept for making traditional cane-sugar blocks. Small huts known as Tup-Aoi serve both as seasonal housing and as open-air areas for boiling cane juice, generating large volumes of bagasse—the fibrous residue left after pressing.

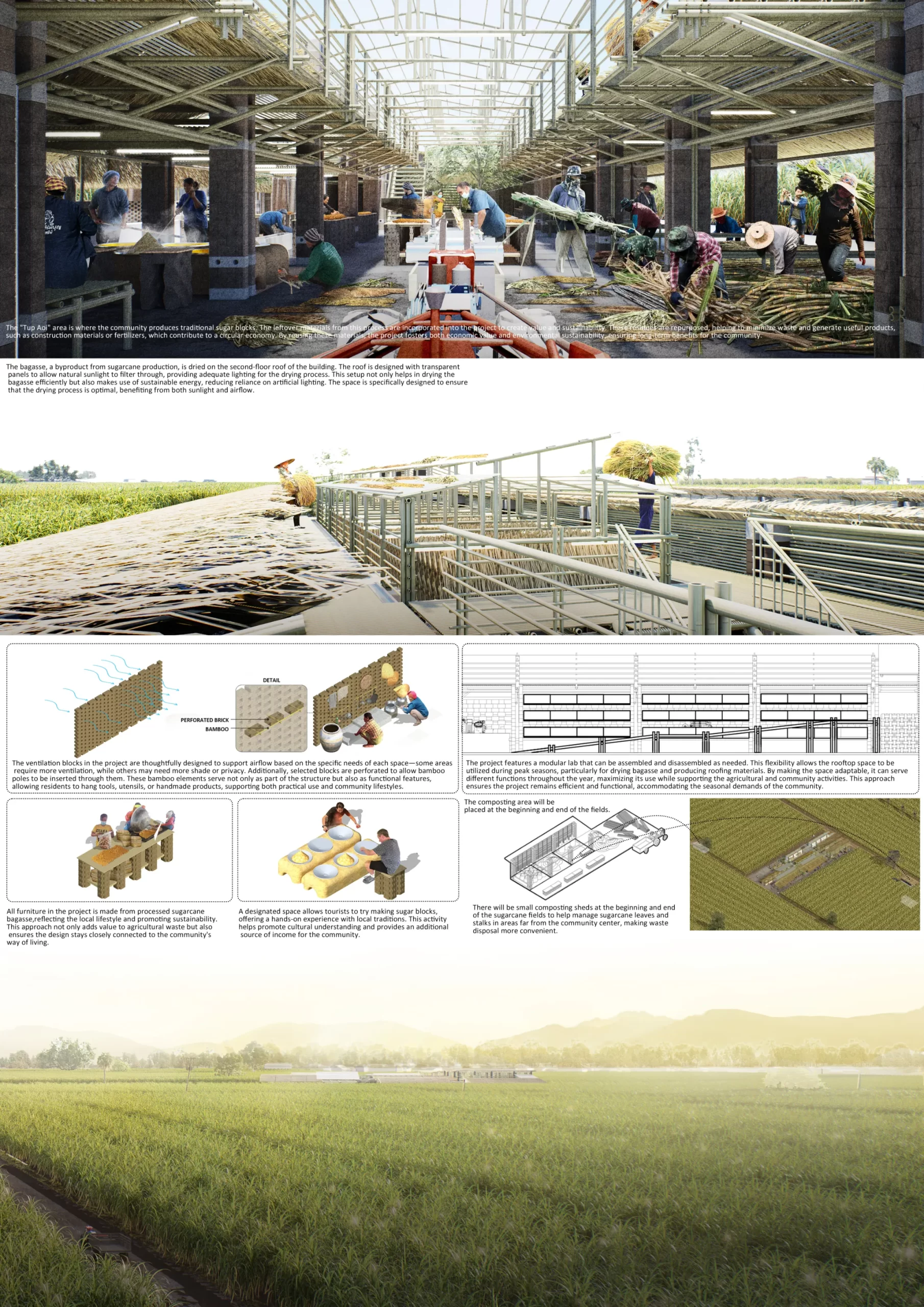

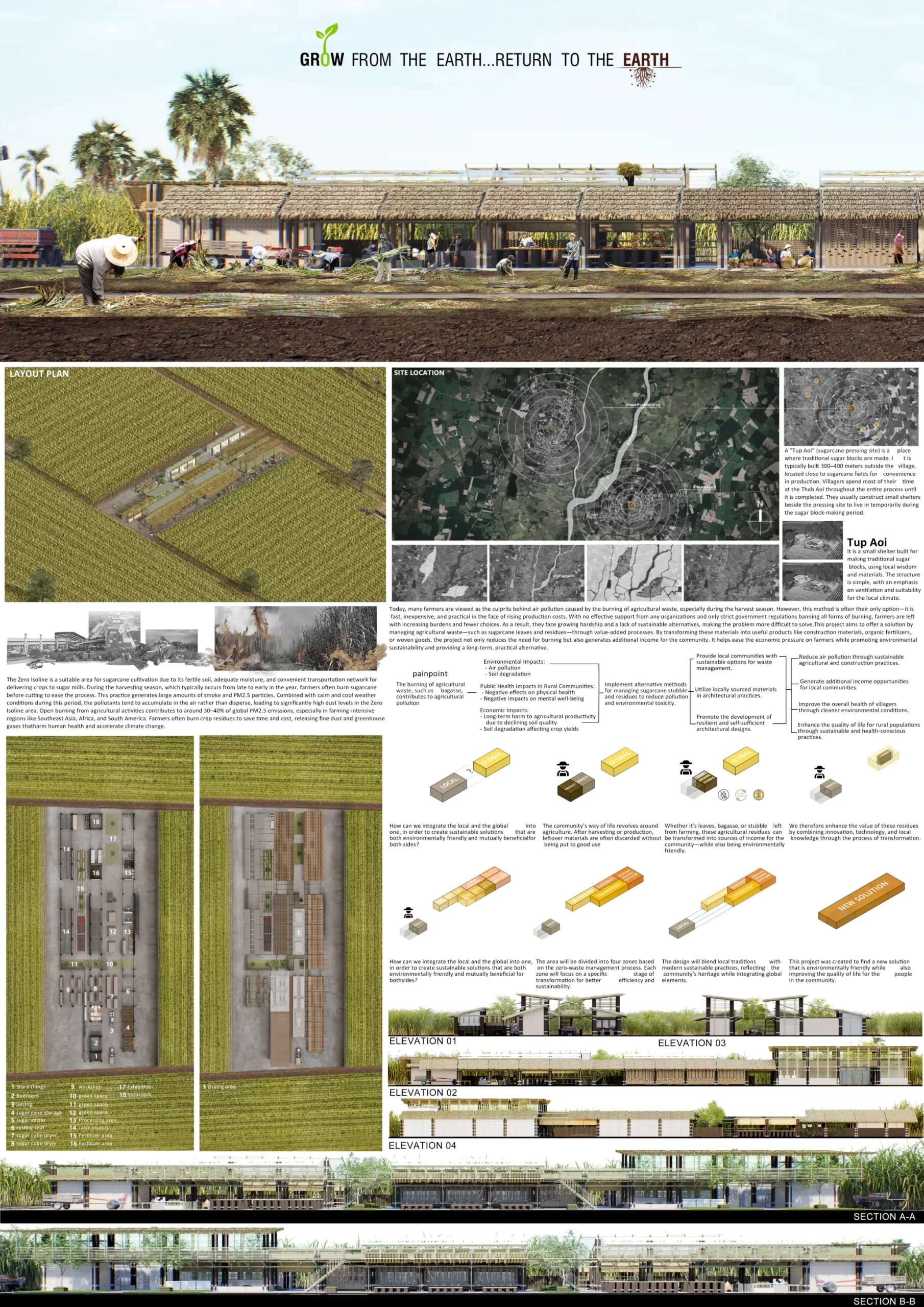

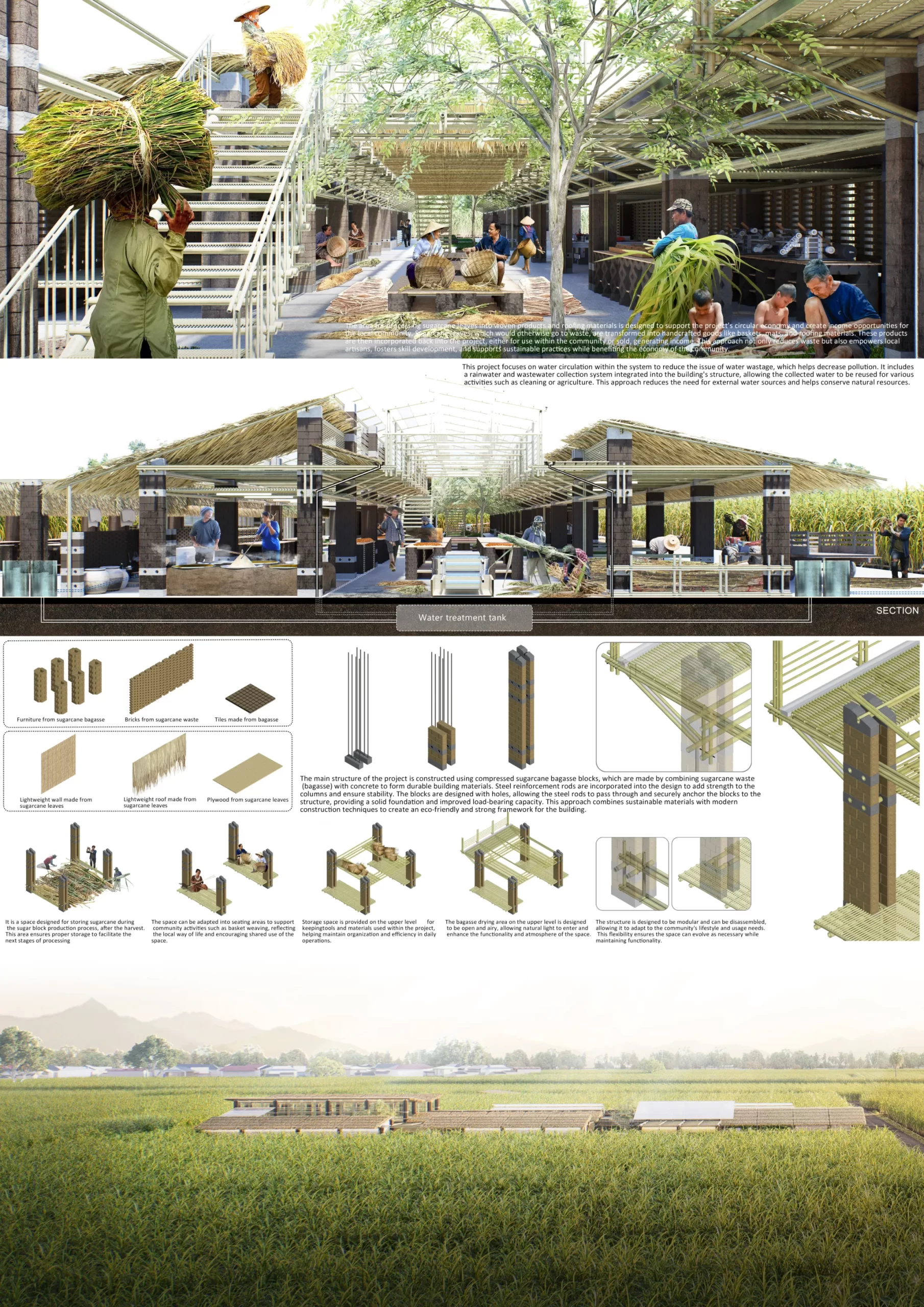

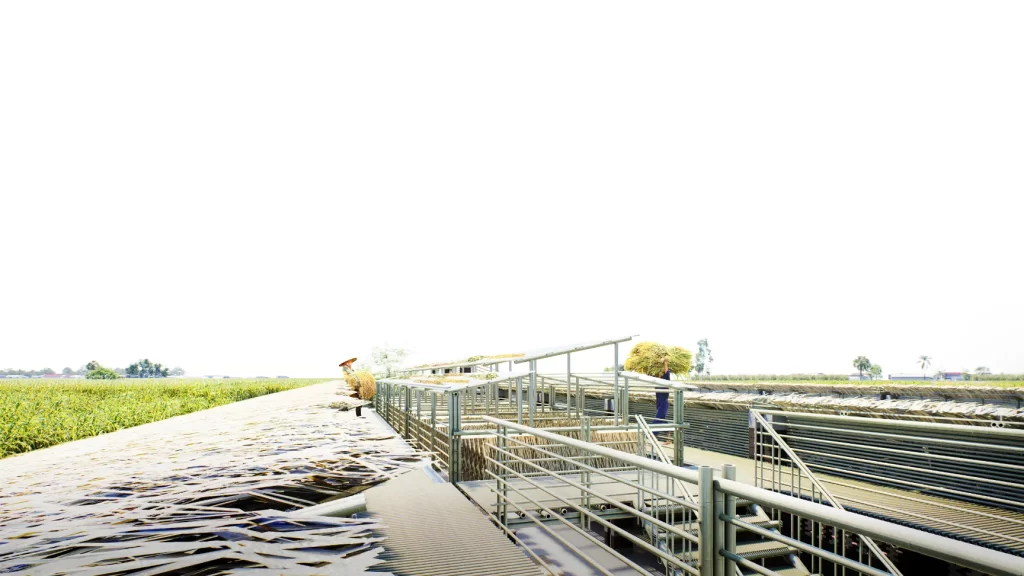

The proposed project recognizes the value of these leftovers. Cane leaves and bagasse are reused as the primary materials for a community center that combines shared activity space, production areas, and raw-material storage. Guided by a zero-waste concept, the initiative turns waste into resources, reduces field burning, and offers villagers new options for handling residues.

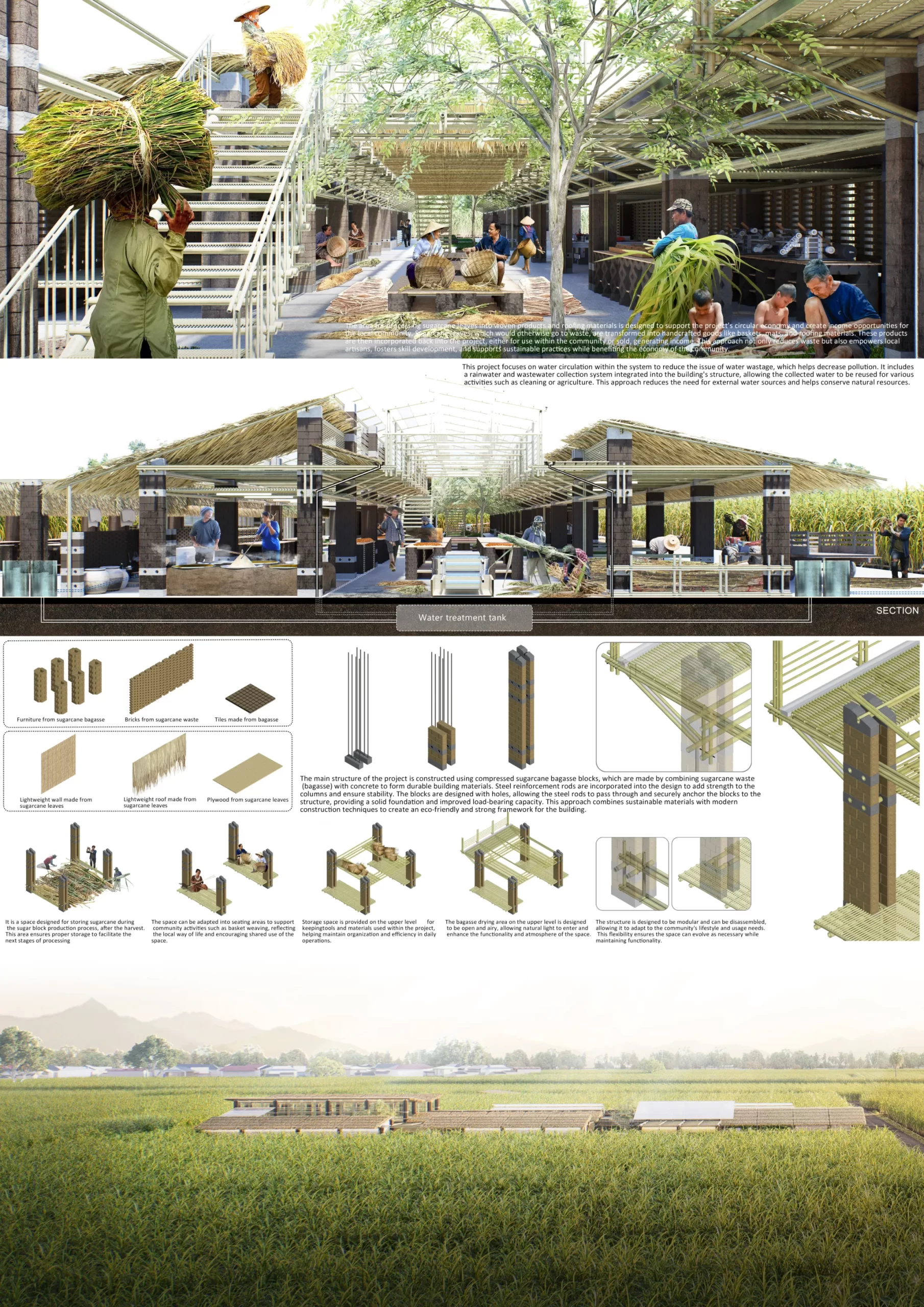

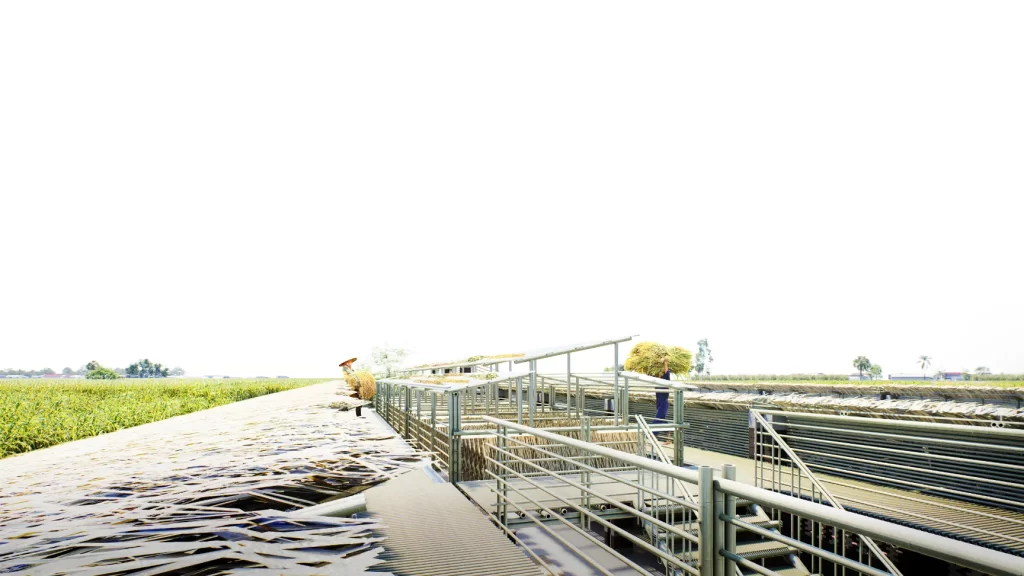

Located in the middle of the cane fields, the center is organized around two existing production streams—cane destined for the factory and cane reserved for sugar blocks. Almost every structural element is made from transformed sugarcane:

Compressed bagasse blocks form load-bearing columns and walls.

Woven leaves become wall screens and roofing.

Bagasse fiberboard is used for interior furniture.

A smokeless kiln converts leaves and bagasse into biochar that improves local soils. Functional zones Sugar-block zone—areas for boiling, stirring, and drying syrup, plus staging yards for stacking cane before pressing. Workshop zone—conversion of residues into building products such as bricks, lightweight roof sheets, wall panels, floor tiles, and fiberboard, supported by drying courts for leaves and bagasse. Biochar zone— a demonstration site where waste cane is turned into soil-enriching biochar without visible smoke. Mini research center—facilities for breeding predatory insects that control early-stage cane pests; mature insects are released into the fields, reducing pesticide use.

During harvest, the center focuses on fabricating panels, roof sheets, bricks, and boards for community projects. While the next crop is growing, selected floor and wall modules can be detached to create open space for village events. Vertical surfaces are fully exploited: parts of the roof serve as drying racks for bagasse and as storage for leaf-woven roof panels, some of which slide into purpose-made wall slots.

By enabling a complete, closed-loop use of sugarcane, the center eases environmental pressure and adds economic value, replacing open-field burning with profitable processing. The scheme is designed as a prototype that can be adapted to other sugarcane-growing settlements and to crops with similar harvest cycles, such as maize or rice. By harnessing local resources, it shows how thoughtful design and spatial management can solve environmental problems—scaling from the village to regional and even global levels.

Showcase your design to an international audience

SUBMIT NOW

Image: Agrapolis Urban Permaculture Farm by David Johanes Palar

Top

GROW FROM THE ERTH…RETURN TO THE ERTH Sugarcane is one of Thailand’s most important cash crops. About ten million rai are under cultivation, most of it in the Northeast, where the climate and soil nutrients are ideal for the plant’s growth. During harvest, farmers often burn the dry leaves to speed cutting. Although convenient, the resulting smoke and fine dust harm local health, especially when resources in the production chain are poorly managed. Ban Nong Khae, Jumjang Sub-district, Kuchinarai District, Kalasin Province, is a village where most households grow sugarcane. At harvest time, farmers divide their crops into two portions: one is sold to a sugar mill, and the other is kept for making traditional cane-sugar blocks. Small huts known as Tup-Aoi serve both as seasonal housing and as open-air areas for boiling cane juice, generating large volumes of bagasse—the fibrous residue left after pressing. Compressed bagasse blocks form load-bearing columns and walls. During harvest, the center focuses on fabricating panels, roof sheets, bricks, and boards for community projects. While the next crop is growing, selected floor and wall modules can be detached to create open space for village events. Vertical surfaces are fully exploited: parts of the roof serve as drying racks for bagasse and as storage for leaf-woven roof panels, some of which slide into purpose-made wall slots.

The proposed project recognizes the value of these leftovers. Cane leaves and bagasse are reused as the primary materials for a community center that combines shared activity space, production areas, and raw-material storage. Guided by a zero-waste concept, the initiative turns waste into resources, reduces field burning, and offers villagers new options for handling residues.

Located in the middle of the cane fields, the center is organized around two existing production streams—cane destined for the factory and cane reserved for sugar blocks. Almost every structural element is made from transformed sugarcane:

Woven leaves become wall screens and roofing.

Bagasse fiberboard is used for interior furniture.

A smokeless kiln converts leaves and bagasse into biochar that improves local soils. Functional zones Sugar-block zone—areas for boiling, stirring, and drying syrup, plus staging yards for stacking cane before pressing. Workshop zone—conversion of residues into building products such as bricks, lightweight roof sheets, wall panels, floor tiles, and fiberboard, supported by drying courts for leaves and bagasse. Biochar zone— a demonstration site where waste cane is turned into soil-enriching biochar without visible smoke. Mini research center—facilities for breeding predatory insects that control early-stage cane pests; mature insects are released into the fields, reducing pesticide use.

By enabling a complete, closed-loop use of sugarcane, the center eases environmental pressure and adds economic value, replacing open-field burning with profitable processing. The scheme is designed as a prototype that can be adapted to other sugarcane-growing settlements and to crops with similar harvest cycles, such as maize or rice. By harnessing local resources, it shows how thoughtful design and spatial management can solve environmental problems—scaling from the village to regional and even global levels.