BACK TO finale_winnerS

Best Design Impact

WASTE UP-CYCLING PARK & WETLAND AWARENESS CENTRE, MUTHURAJAWELA

The improper disposal of garbage has now become one of the most threatening global fears. The sheer amount of waste accumulated in oceans and landfills obliterates eco systems and its impacts will be felt by all humans, flora and fauna alike. While it is a global responsibility, Sri Lanka too have been significant contributors to this threat. The issue of improper garbage disposal has so far been swept under the carpet, but recent events such as the devastation of Meethotamulla has made the bitter truth hard to ignore: the need for solid waste management.

Sri Lanka , a small island of 65,000sq.km. located at the heart of Indian Ocean, houses a multi-ethnic and multi-cultural population of over 21 million. Though it has been coined the term “Pearl of the Indian Ocean”, Sri Lanka is plagued by its contribution to the environmental and as socio - economic devastation caused by improper management of municipal solid waste. Until the devastation of Meethotamulla, open dumping was completely overlooked.

The project concentrates on the management of municipal solid waste as an innovative source material which could be altered & improved rather than discarded. Whilst breaking down the stigma of waste being a mere threat to the environment observing it as a value addition and raise awareness on the importance of waste management and Upcycling. Moreover, rejuvenate the already disturbed wetland system in Muthurajawela by strengthening the qualities of the Wetland via public and professional interventions.

• To provide a systematic platform to investigate and study, solid waste materials and the processes involved in order to establish facts and reach new conclusions...

• To co-create a facility which conserves the wetlands while raising awareness on the importance of the wetlands while responding to a critical issue in relation to waste.

• To merge the research & development of solid waste to its innovative uses where users compliment each other.

• Provide flexible spaces that invoke innovation & aid in materializing thought & ideas.

• Provide a platform for innovators to display their works to the public; thus increasing the potential to improve & implement.

“VERTICAL FACTORY: BUILDING UPWARDS”

Project investigates the possibility of an alternative to inefficient horizontal sprawl by considering the prospects of a new vertiginous architectural typology in the form of a vertical factory devoted to the stabilization and re-integration of waste management and upcycling. This specific approach was followed with the reasoning of following aspects.

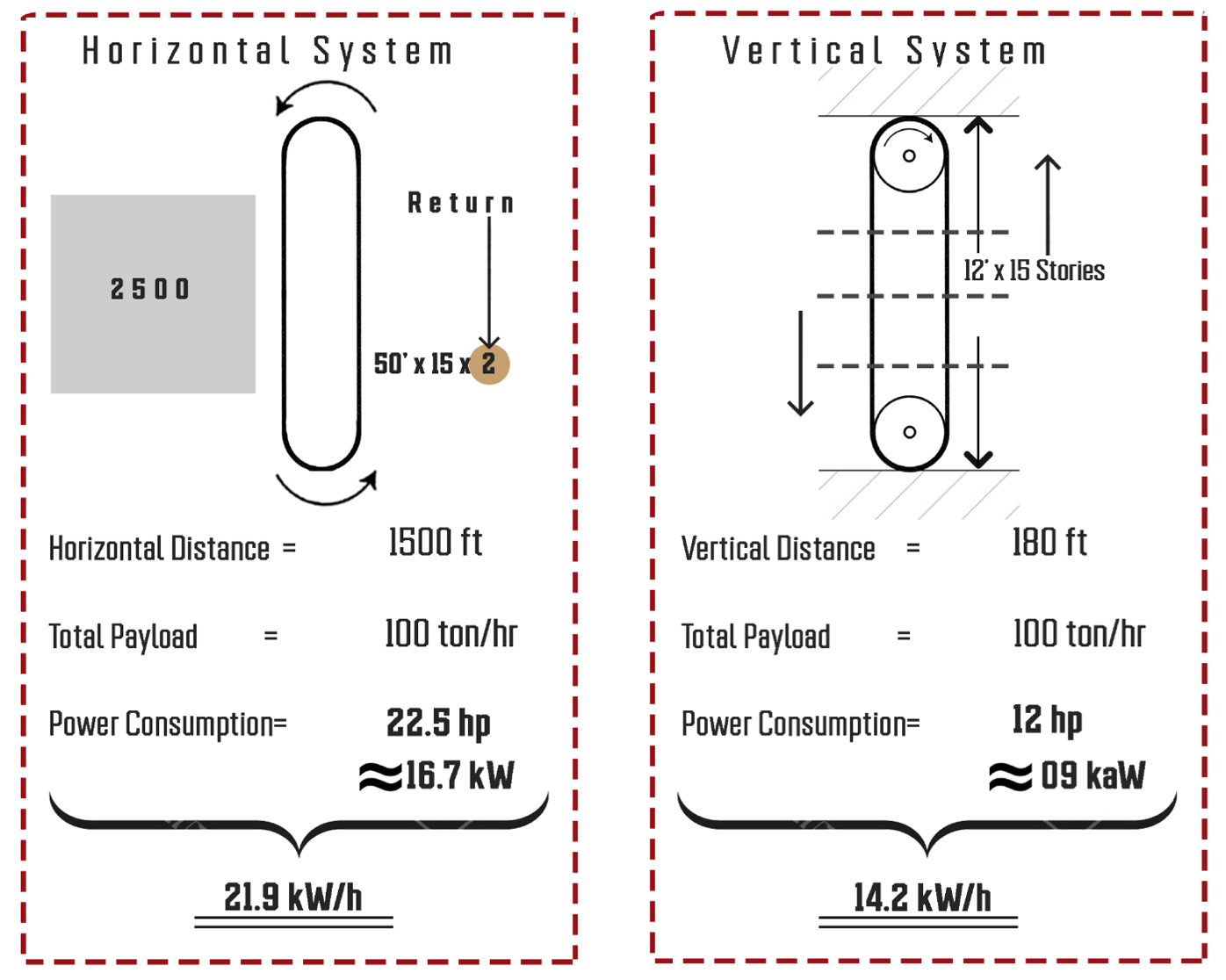

Comparison of a horizontal conveying system vs the Vertical Conveying system.

* It was assumed that the horizontal system would have the same amount of departments as the vertical system (15 departments) where as one department would have a total floor area of 2500 sqft, hence traveling a distance of 50 feet across each department floor. But in the vertical system this distance will be only 12 feet since the departments are stacked on top of each other. Moreover it is important to note that in the vertical system energy required for the return line can be disregarded as the gravitational force can be used to bring down the return goods in the conveyor system while in the horizontal the same amount of energy used in the feeding conveyor will be utilized during the return line.

Comparison of a horizontal conveying system vs the Vertical Conveying system.

* It was assumed that the horizontal system would have the same amount of departments as the vertical system (15 departments) where as one department would have a total floor area of 2500 sqft, hence traveling a distance of 50 feet across each department floor. But in the vertical system this distance will be only 12 feet since the departments are stacked on top of each other. Moreover it is important to note that in the vertical system energy required for the return line can be disregarded as the gravitational force can be used to bring down the return goods in the conveyor system while in the horizontal the same amount of energy used in the feeding conveyor will be utilized during the return line.

• Horizontal Distance travelled from the MRF facility to the tower : 400 ft

• Total Power Consumptions for the horizontal conveying = 7 hp approximately equals to 5.2kW

Showcase your design to an international audience

SUBMIT NOW

Image: Agrapolis Urban Permaculture Farm by David Johanes Palar

Top